We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

Ridgeway Services

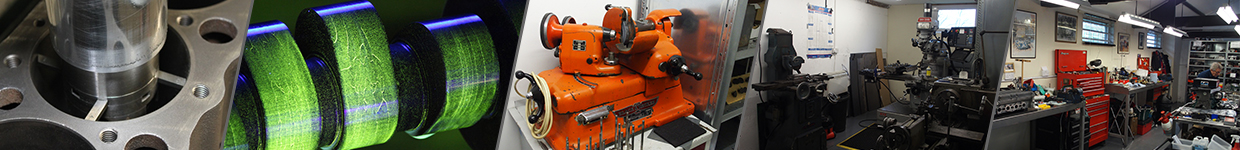

Our engine builders have a combined experience of over 100 years in the field of motorsport.

When building a new race engine, we only use the finest components from well-respected and race-proven suppliers. We also have components manufactured in the UK to our own designs and specifications.

When rebuilding an existing race engine, we strip, clean and assess everything. Major components are crack tested and replaced if necessary.

Whether it’s a new build or a rebuild, all race engines get fully tested and run-in on the dyno. This allows us to ensure that the engine is performing as it should, allows for fine-tuning of the setup and helps to avoid installation issues.

Ridgeway offers crack testing facilities for both magnetic and non-magnetic engine components. In both cases, parts are thoroughly cleaned and then heated.

Magnetic parts are dowsed with a UV dye solution which contains magnetic particles. The parts are then put on a machine which uses electromagnetism to draw the dye into any imperfections. The parts are inspected under UV light, which highlights imperfections such as stress fractures. The parts are then cleaned again and de-magnetised.

Non-magnetic parts are sprayed with a penetrating dye, which is left to soak in before being rinsed off. A developer powder is then sprayed on which highlights any imperfection on the part under visible light

The process of balancing internal engine components is incredibly important for reducing vibration. Vibrations, if severe enough, can lead to premature component wear and even component failure. At Ridgeway, we employ both static and dynamic balancing techniques when building your engine.

Reciprocating parts are statically balanced. We strip and weigh everything from the pistons and con rods, right down to the gudgeon pins and rod bolts. All reciprocating parts are then lightened to match their lightest counterpart as closely as possible.

Rotating parts, such as the crankshaft, flywheel and pulleys are assembled together and placed onto the balancing machine. The crank is then spun up via a belt, instead of being directly driven, which ensures only vibrations in the assembly are being measured. Material is then removed or sometimes even added in order to achieve correct balance.

- Cylinder head porting

- Cylinder head and block skimming

- Cylinder block boring and honing

- Cylinder block relining

- Valve seat and guide replacement

- Con rod re-bushing

- Line boring